2023-08-30

Strict operation and market environment

Regardless of design or application, industrial compressors are often subjected to harsh operating conditions. Today, market and regulatory conditions are just as difficult. Growing global demand boosts global production and competition. Rising energy prices and increasingly stringent government regulations incentivize the development of environmentally friendly devices that are more energy efficient. And end users everywhere are looking for general contract products and total support solutions.

Compressor solutions can help

As a supplier of bearings and engineering solutions for the compressor industry, we have been helping original equipment manufacturers and operators meet these and other performance challenges for many years. In close cooperation with several manufacturers, a wide range of quality solutions are available that make the production and operation of compressors stronger, safer and more energy efficient.

Compressor industry, applications, cases, solutions

Scroll compressor

Scroll compressors are small in size and are a small but important part of the large compressor market. Ideal for domestic refrigerators and HVAC systems, scroll compressors have far fewer parts in total than reciprocating compressors, thus providing better reliability and energy efficiency. Bearing solutions optimize the design benefits of these scroll compressors in several ways.

Reciprocating compressor

Reciprocating, or piston air compressor, is an earlier design in compressors, but it is still widely used in a variety of applications with high pressure and low exhaust volume. Inevitably high operating temperatures can cause friction losses and lubrication problems for bearings. High temperature, low maintenance solutions for reciprocating compressors. Whether you're designing new equipment or upgrading equipment in operation, bearing and bushing solutions help extend service life while reducing maintenance and operating costs.

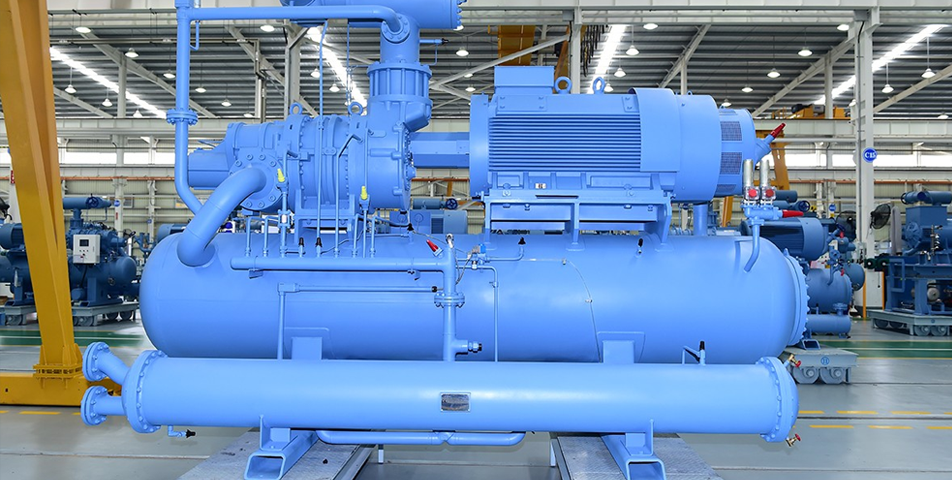

Twin-screw compressor

Twin-screw compressors are now more popular due to their quieter operation and continuous and stable supply of compression media. Compared to reciprocating piston equipment, twin-screw compressors are more reliable and energy efficient, and therefore less expensive to operate. Engineering and application knowledge can help optimize the performance of twin-screw compressors, thereby reducing operating costs. Whether for compressed air, industrial gases or refrigerants, a range of solutions to improve the performance of twin-screw compressors.

Centrifugal compressor

Centrifugal compressors are commonly used in large HVAC systems where high-pressure gas is circulated through a heat exchanger. The coolant medium is accelerated through one or more impellers and subsequently the kinetic energy is converted to static pressure energy. Today's centrifugal compressors must deliver robust, ever-improving energy efficiency performance for air compressor applications. In wastewater treatment facilities, for example, ventilation accounts for about 70% of total energy use. From traditional designs to bearings lubricated with pure refrigerants, a variety of special bearing solutions have been developed for centrifugal compressors. No matter the size, load or location of the compressor, the solution helps it operate more reliably and cost-effectively.

Solutions are used in several industries: wastewater treatment, power generation, food and beverage, pharmaceuticals, chemicals, pulp and paper industries, cement.