2023-08-30

Industrial transmission, wide range of conditions and requirements

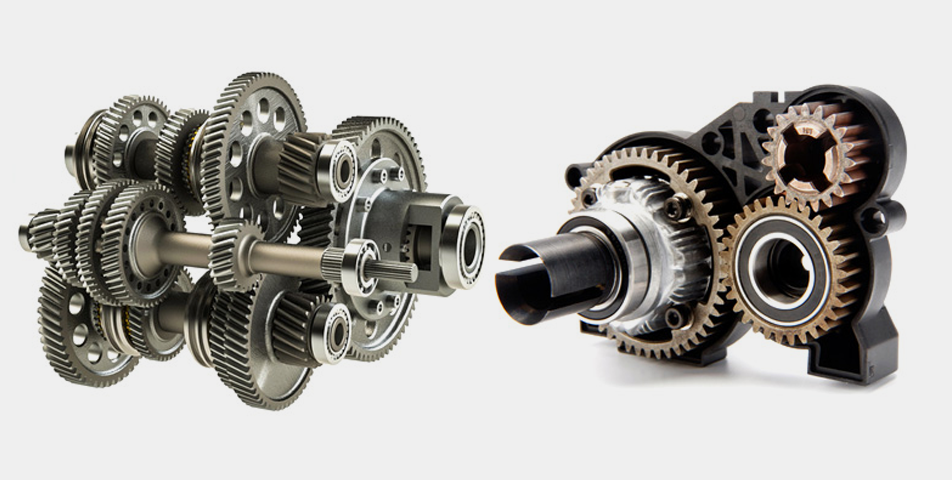

Gear units and driveline systems can operate in almost every industrial process and are available in a wide range of possible shapes and sizes, so they are subject to their wide range of operating requirements and conditions. But regardless of the industry or application, all industrial drives face a common challenge: they must operate as reliably, efficiently and cost-effectively as possible.

Industrial gearbox solutions to meet these requirements

can help manufacturers and users find ways to optimize transmission performance and reliability. By using a systems approach, we can help you realize the full potential of your gear and improve performance and reliability in several ways:

High torque

Reduced size design

Long service life

Gain operational reliability

Improve energy efficiency

Industrial gear box industry, applications, cases, solutions

Gear motor

Gear motor

Gear drives are sold in relatively large quantities and are used in many different applications, such as material handling, packaging equipment and automation. The fierce competition in the market means that agents must find ways to achieve more cost-effective design and agency processes while continuing to improve technical performance.

Provide a high level of engineering capabilities and high performance products. Working with your customers, you can achieve cost-effective designs without much planning. With a range of efficient sourcing, solutions help gear motor agents:

Streamlined agent

Shorten time to market

Increase torque

Lower operating temperature

Reduced noise level

Helical and helical bevel gears

Screw and umbrella screw gear drives are designed for harsh applications such as mining conveyors, paper machines, extruders, continuous casting machines or port cranes. They must be able to provide a high degree of operational reliability in harsh environments such as high temperature, humidity and dust, as well as at low speeds and heavy loads. The challenge is to provide cost-effective and modular agents while enhancing performance.

; It is unique in its ability to provide a high level of engineering capabilities, high-performance products, and an efficient supply network. With a systems approach and modular thinking, you can improve device performance, reduce design and agency costs, and increase profitability.

Increase torque

Reduced heat generation

Increased capacity to carry external loads

Reduce noise level

Improved operational reliability

Shorten time to market

Custom gear unit

Large, customized gear drives are tailored to the specific needs of various industries, such as cement, steel, power generation, mineral brokerage, wind power and conventional power generation. Its harsh operating conditions include high torque, heavy external loads, shock loads, severe environmental pollution, and speed variations. Reliability and operational performance are critical, placing high demands on the design process.

To meet these challenges, the combination of high level engineering services and high performance products and condition monitoring systems provides unique capabilities. You can achieve superior gear operation and transmission performance in several ways:

Improved operational reliability

Increase transmission torque

Improved external carrying capacity

Shorten time to market

Moving and static planetary gears

Small to medium-sized planetary gears must address serious application challenges, such as wheel drive in agricultural and construction locomotives, and rotary drive in construction equipment and wind turbines. They are operated under heavy cycle and highly polluted conditions with heavy external loads.

provides standard and specific high level engineering capabilities and high performance products for a variety of specific locations. With a range of efficient sourcing, solutions can help agents:

Increase torque

Improved external carrying capacity

Development of lighter and more compact configurations

Streamlined agent

Shorten time to market

Simplify the installation process

Drive System Services - Industrial applications

This is the main goal of business managers in every industry. Achieving these goals requires a reasonable combination of operational reliability, energy efficiency and lower service requirements.

Driveline Services, by optimizing the way your driveline is integrated into the agent process, we can help you improve the performance of your gear units to meet economic targets at every stage of their life cycle. No matter what the industrial process. — Steel agents, mining and cement, port cranes and moving Bridges in order to:

Increase agency power

Total cost of reduced service life

Improve energy efficiency

Drive System Service - Rolling mill

For rolling mills, impact loads, vibration, heat, dust and rapidly changing operating conditions are a constant threat to the reliability of the drive system. The volume of proxies can significantly affect torque and power requirements. Maintenance operations are often time consuming and potentially dangerous. Product quality can be negatively affected by system vibration, improper design, or unreliable functionality of support systems.

Drivetrain services can help mills meet all these challenges and more. Understanding that the mill is a complex system in which agents, drivetrains and products interact can help you achieve several unexpected goals:

Improved rolling time and reliability

Full focus on health, safety and environmental factors

Produce more quality products

Higher performance and more output

Drive System Service - Steel Agent

As the core of the steel plant, the blast furnace and converter must be kept running properly. So, keep the row? And the reliability of the transmission system that the conveyor is always running on is equally important. Unfortunately, end temperatures, shock loads and contaminants make it difficult to avoid downtime, as well as forcing the drivetrain beyond its design parameters. The result?

What was the result? As drivetrain functions degrade, torque or power losses limit performance. Ultimately, failures lead to costly, unplanned downtime and time-consuming, dangerous repairs.

By optimizing the way your drivetrain is integrated into the agent process, we can help you improve the performance of your gear units to meet economic targets at every stage of their life cycle. Advantages include:

Increases uptime and improves reliability

Full focus on health, safety and environmental factors

Higher performance and more output

Improved and effective maintenance

Engineering Transmission solutions

The gear box of the mill is used to drive the feed frame of the steel belt pickling agent line, which is prone to problems. The process operates continuously and acts on a large scale in dirty, hot environments. The impact between the loading tool and the work roll creates a shock load and causes frequent failure of the gear box and coupling. The customer understands the total solution package.

After analyzing these gearbox failures, it was determined that the problems were caused by an inappropriate bearing configuration on a particular gearbox shaft. The configuration includes a pair of tapered roller bearings of rare size. This has very low reliability for bearings, and their maintenance and replacement processes are complex and time-consuming. In addition, the bearings are very expensive and the delivery time can be up to a year.